This article explains when live testing is permitted, and how to meet the necessary conditions of Regulation 14 of the Electricity at Work Regulations 1989.

Live testing is permitted, but only where all three conditions of Regulation 14 of the Electricity at Work Regulations 1989 have been met. This article summarises these conditions as they relate to live testing activities.

Regulation 14 of the Electricity at Work Regulations 1989 (EWR) states that:

No person shall be engaged in any work activity on or so near any live conductor (other than one suitably covered with insulating material so as to prevent danger) that danger may arise unless:

(a) it is unreasonable in all the circumstances for it to be dead; and

(b) it is reasonable in all the circumstances for him to be at work on or near it while it is live; and

(c) suitable precautions (including where necessary the provision of suitable protective equipment) are taken to prevent injury.

This regulation applies to all activities during which it is necessary to work in close proximity to energised and exposed or inadequately insulated live parts where this may foreseeably give rise to danger. This would include activities such as carrying out the safe isolation procedure, checking the polarity of an incoming supply and testing earth fault loop impedance or RCD functionality. This is confirmed in paragraph 207 of the Electricity at Work Regulations 1989. Guidance on Regulations (HSR25) published by the Health and Safety Executive (HSE).

Let’s consider the three requirements in Regulation 14 that must be met before live work may proceed.

1. It is unreasonable in all the circumstances for the conductor to be dead

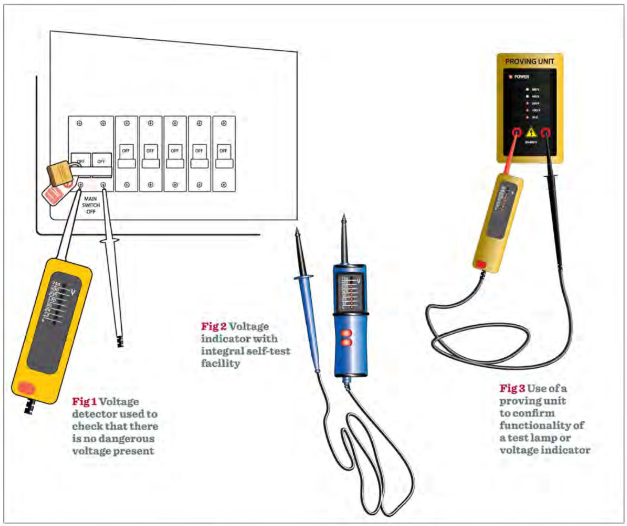

It is reasonable for testing to take place on or near to a live conductor where the information provided by testing can only be obtained with the conductor energised. For example, the industry-accepted procedure for performing safe isolation requires the supply to the installation or the part thereof to be worked on to be energised initially and to be proven to be energised using a suitable voltage indicator or test lamp.

Similarly, it is reasonable to carry out earth fault loop impedance testing on an energised installation to confirm that the actual, as installed, impedances of circuits are sufficiently low to allow the disconnection times of BS 7671 to be met under fault conditions. However, such testing should only be performed where the protective measures used require a knowledge of earth fault loop impedance (643.7.3.1).

In the case of certain sources of supply, such as PV inverters, this information may be obtained from the manufacturer’s data removing the need for such testing which may not provide reliable data in any case due to the nature of the output of the device.

It should also be noted that where protection is provided by automatic disconnection of supply (ADS), the effectiveness of this protective measure ‘downstream’ of an RCD may be verified by confirmation of the continuity of protective conductors so removing the need for earth fault loop impedance testing at that point within the installation (643.7.1 a) and b)). Knowing the value of resistance for a circuit’s line and protective conductor (R1 + R2) allows the earth fault loop impedance to be verified using the equation

A value of earth fault loop impedance for a circuit within the installation may be obtained using the above formula, limiting live testing to measuring of the earth fault loop impedance external to the premises (Ze) only.

It should be noted however that, whilst live testing should only be undertaken in line with Regulation 14, a value of Ze obtained by enquiry cannot identify defects external to the consumers installation and as such will not show the actual site condition impedance.

Live testing is often carried out to allow the prospective fault current at the origin to be determined. Appendix 14 of BS 7671 advises that:

In domestic (household) premises, where a consumer unit to BS EN 61439-3 is used and the maximum prospective fault current declared by the distributor is 16 kA, it is not necessary to measure or calculate prospective fault current at the origin of the supply.

2. It is reasonable in all the circumstances to be at work on or near a conductor while it is live

In some cases, equipment may need to remain energised to permit fault finding. However, it does not follow that, having found the fault, there will necessarily be justification for subsequent repair work to be carried out live (HSR25: paragraph 220).

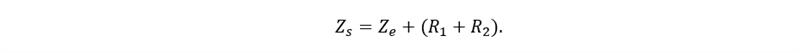

Justification for exposing live terminals solely to verify the correct operation of a voltage indicator or test lamp before and after use is arguably more problematic in terms of this condition. Whilst the use of a test lamp or voltage indicator on an energised circuit to prove dead is essential and unavoidable, it is possible to confirm the functionality of such test devices prior to and after such testing by either the integral self-test facility of some voltage indicators (Fig 2), or by the use of a suitable proprietary proving unit (Fig 3).

Such methods not only remove the need to expose live parts until it is necessary to confirm that the conductor is energised, but also the need to access another live part after the conductor has been isolated to confirm that the test device is still functioning correctly.

3. Suitable precautions are taken to prevent injury

In the context of live testing, suitable precautions to prevent injury include:

- only allowing suitably competent persons who are familiar with the type of installation, the test devices to be used and the work activities to be performed to carry out testing, and

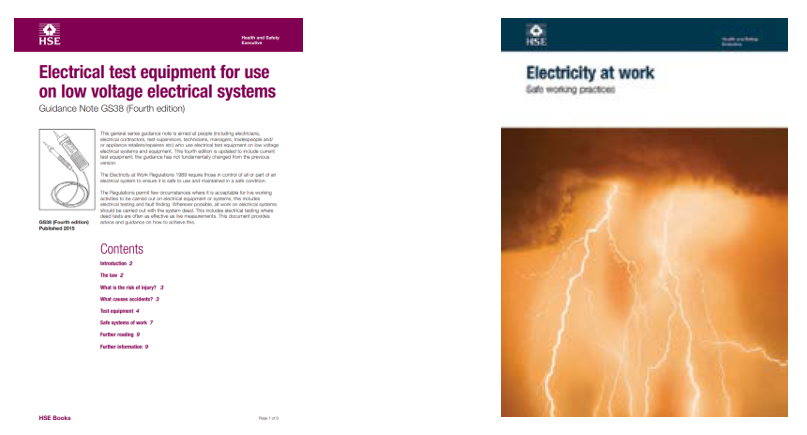

- the use of suitable testing devices meeting the requirements of relevant product standards and the recommendations given in Electrical test equipment for use on low voltage electrical systems (GS38), and

- the use of suitable protective equipment as appropriate to the exposure risk (HSR25: paragraphs 221 and 222).

Where for example routine testing or fault finding is carried out on energised equipment, a suitable precaution might be to cover live parts with a transparent insulating screen in which holes are drilled to enable access to be made to test points. In some cases, it might be appropriate to bring leads out from a test point, to a suitable multi-pin socket-outlet, permitting the use of test equipment in a manner that is not only safer but may also reduce the time required to carry out the necessary testing.

Persons carrying out work on or near a live conductor have a legal responsibility for the safety of other persons who may be affected by their actions (EWR: regulation 3). They must therefore take suitable precautions to ensure effective control of the area where live testing is being carried out.

A risk assessment should be carried out to determine an appropriate course of action to suit the particular circumstances. A record of this assessment will be required where an employer has five or more employees.

The guidance provided in the Electricity at Work Regulations 1989. Guidance on Regulations (HSR25), Electricity at work, safe working practices (HSG85) and Safety in electrical testing at work (INDG354) published by the HSE are invaluable to anyone carrying out live testing activities or having responsibility for those carrying out such work.

HSR25, GS38, HSG85 and INDG354 can be downloaded free of charge from http://www.hse.gov.uk/pubns/index.htm

Further information on safe isolation can be found in Best Practice Guide 2 Guidance on the management of electrical safety and safe isolation procedures for low voltage installations published by Electrical Safety First. This, and all other Best Practice Guides, can be downloaded free of charge from http://www.electricalsafetyfirst.org.uk/electrical-professionals/best-practice-guides/

Certsure has produced a safe isolation pocket guide within the NICEIC Pocket Guide App that allows electrical engineers and electricians to access this important information while they are working and so keep themselves and others safe. The NICEIC Pocket Guide App is available from the App store for iPhone and iPad and Google Play for Android phones and tablets.