This article looks at the issues that may arise when it is necessary to replace an electric shower in an existing premises

This article looks at the issues that may arise when it is necessary to replace an electric shower in an existing premises. It considers the assessment of the existing installation prior to work commencing, the assessment of current-carrying capacity taking into account ambient installation conditions and the selection of a suitably rated replacement unit.

Introduction

Prior to additions and alterations being made to an electrical circuit it is necessary to determine whether the installation is suitable for the alteration, as outlined in regulation 132.16.

Thereafter, an assessment should be made to determine, so far as is reasonably practicable, the current capacity of the installed cable based on its uncorrected current rating (It) after the application of any relevant correction factors for ambient conditions such as grouping with other circuits (Cg) and presence of thermal insulation. This is necessary as the original design intentions are not known and, increasingly, any such original design considerations may have been affected by the addition of extra thermal insulation placed over the conductors.

Having determined the current-carrying capacity for the cable in its as installed condition (Iz), a suitably rated replacement shower unit can be obtained and fitted.

Why reverify the circuit

Electric showers come in a variety of ratings, usually given in the unit of power; Watts, or kilowatts (kW). Generally, the available ratings are between 7.5 kW and 10.8 kW. Historically however, electric showers were only available towards the lower end of these ratings, which can lead to an incompatible shower being installed when replacing a dated shower and using a ‘one size fits all’ approach. This can result in overloading of the cable and circuit accessories, potentially leading to a fire hazard.

Reverification of the circuit

When replacing a shower, a simple verification process should be carried out to ensure the circuit is suitable for the altered load. The steps for this are detailed within this article for the following scenario:

A new electric shower is to be installed to an existing circuit. The client has supplied a 9 kW rated shower, which is to replace a faulty 7.5 kW device. The cable serving the shower is a ‘twin and earth’ type with 6.0 mm2 live conductors and a 2.5 mm2 circuit protective conductor (cpc). The circuit is protected by a 32 A circuit breaker to BS EN 60898, and a 30 mA Type AC residual current device (RCD) to BS EN 61008-1. The measured voltage at the shower position is 245 V. The most detrimental part of the cable run is through the loft, where the cable is covered by 100 mm of thermal insulation for several metres (installation method 100). The cable is not grouped with other circuits and no other rating factors apply. A 40 A double pole isolator is located outside of the bathroom.

(i) Determine the design current rating of the new shower (Ib)

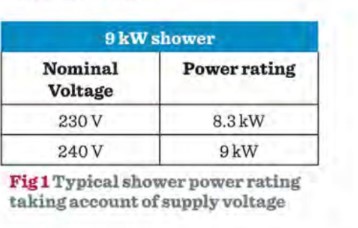

Shower manufacturers will declare the power rating of their devices; the rating is generally provided at two nominal voltages, 230 V and 240 V. The different voltages yield different power ratings. This is due to the fixed resistance of a shower. An example of a rating that comes within the manufacturer’s instructions is reproduced as Fig 1.

As the shower is a resistive load, the higher the voltage, the greater the current demand. The designer must consider the actual voltage at the point of installation. The tolerance for a 230 V nominal supply is -6% + 10%, which is a range of 216 V to 253 V. Without prior knowledge of the voltage, the designer should assume a voltage at the upper range of the scale. When using measured values, the designer must consider that voltage varies depending on the load of the network.

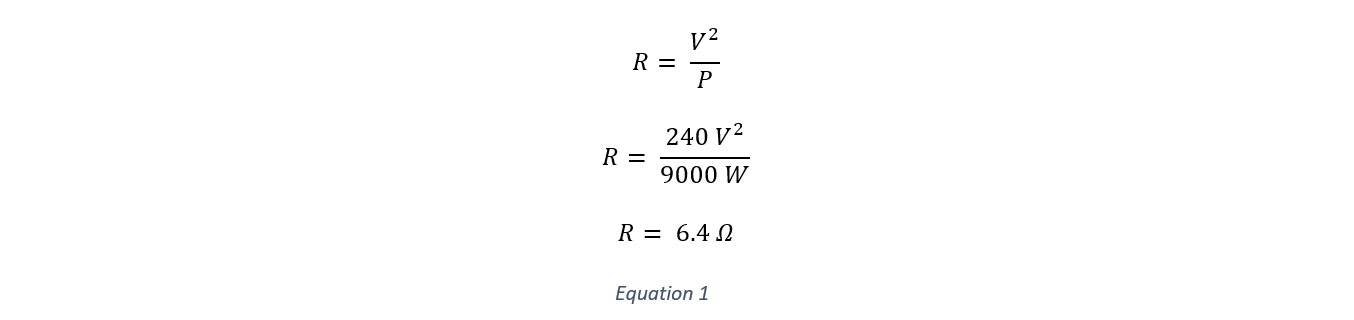

An effective way to obtain the design current is to first determine the resistance of the shower as shown below:

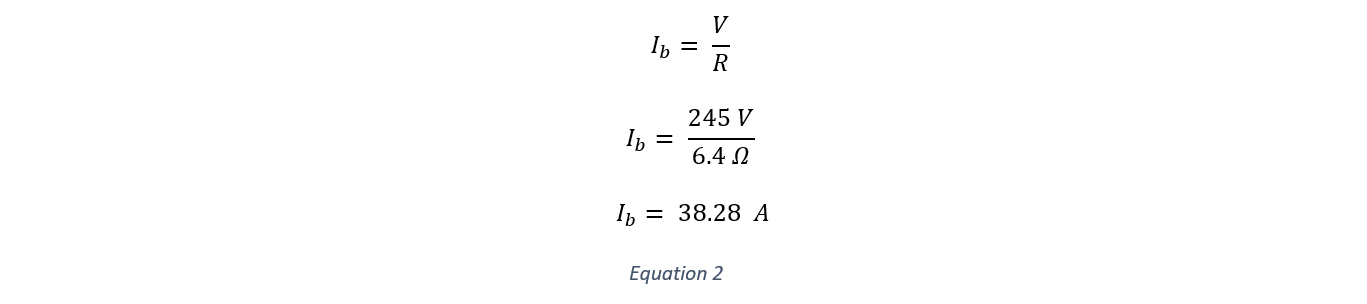

With the resistance known, the current can be found with the known voltage of the installation. Equation 2 determines this to be 38.28 A

With the resistance known, the current can be found with the known voltage of the installation. Equation 2 determines this to be 38.28 A

If 230 V was used to determine the current of the proposed 9 kW shower, the current demand would be 35.9 A

If 230 V was used to determine the current of the proposed 9 kW shower, the current demand would be 35.9 A

The shower being replaced that is rated at 7.5 kW had a current demand of 31.9 A at 245 V.

(ii) Determine the current carrying capacity of the cable (Iz)

To determine the current-carrying capacity of the cable (Iz), the tabulated value of current (It) is first required, this is then adjusted due to any correction factors that may apply to the circuit. Appendix 4 of BS 7671 contains tabulated values of current-carrying capacity, and the correction factors that may be applied to these values.

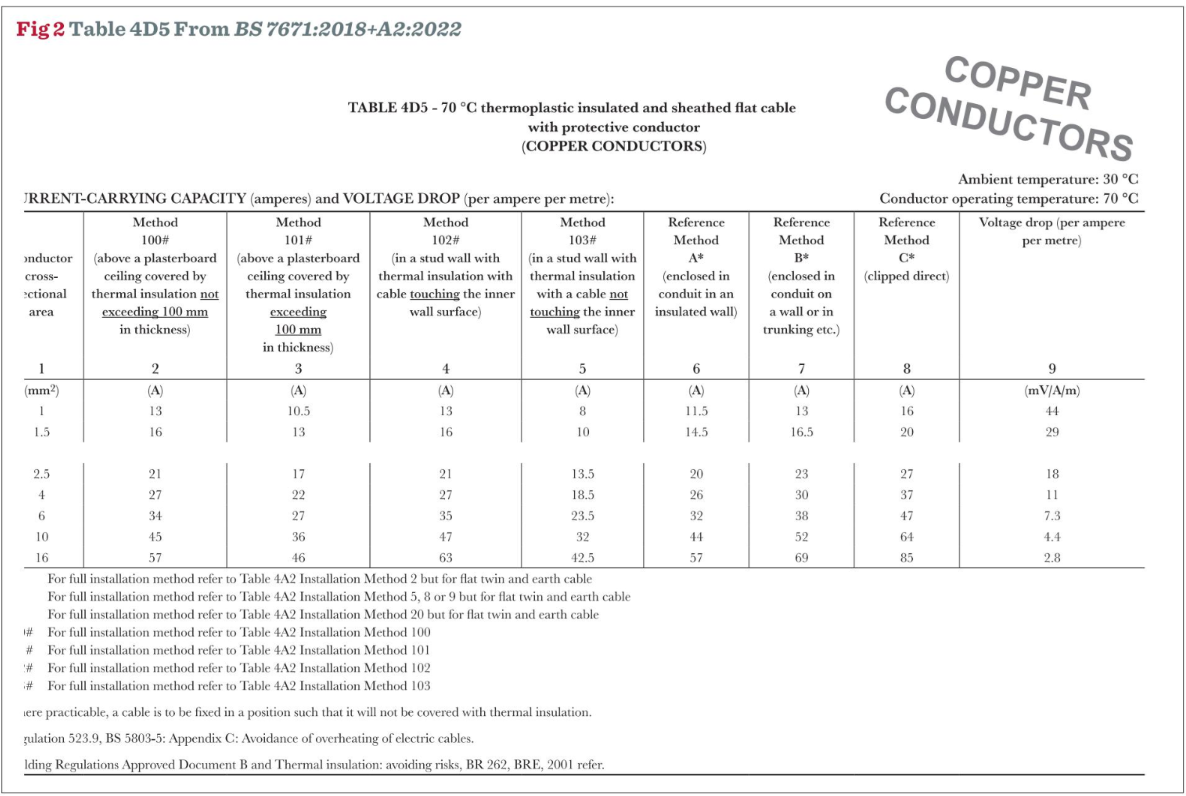

Table 4D5 from BS 7671, reproduced as Fig 2 gives current-carrying capacities for PVC insulated and sheathed flat 'twin/ three-core and earth' type cables.

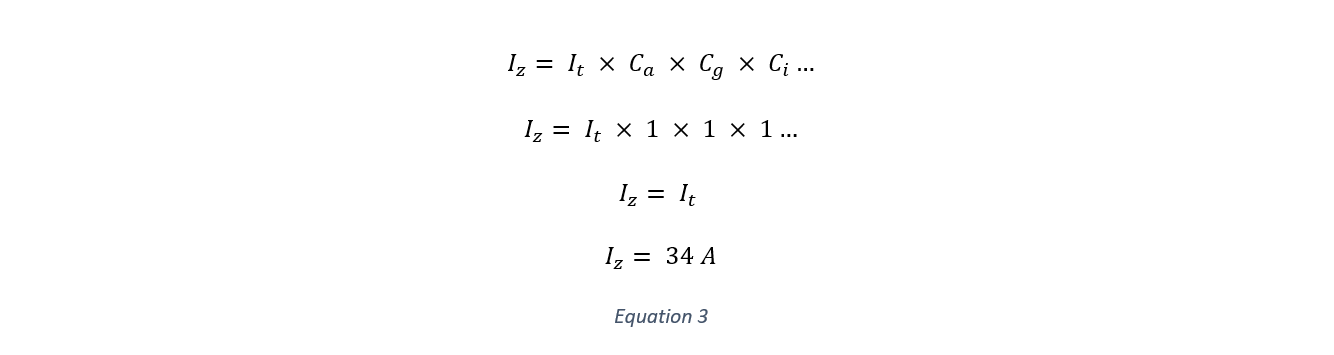

From Fig 2, the tabulated current rating (It) of insulated and sheathed flat cable having 6.0 mm2 live conductors using Method 100 is 34 A. To determine the cable's current carrying capacity (Iz), the relevant correction factors shall be applied to this value, although as there are no correction factors to apply for this scenario, Iz equals It.

(iii) Ensure coordination between the load (Ib), the protective device (In) and the cable (Iz).

The requirements of indents (i) and (ii) of regulation 433.1.1, which is condensed into the expression shown below, shall be met to ensure the cable is suitably protected against overload.

Where:

Ib = design current

In = Current rating of protective device

Iz = Cable current carrying capacity

The values from the scenario can now be input to the expression, as shown below.

The existing circuit-breaker and cable are not suitable for the proposed load. Equation 4 shows the load current is greater than the protective device and the cable rating.

Regulation 433.1 states:

Every circuit shall be designed so that a small overload of long duration is unlikely to occur.

If the proposed shower was installed to this circuit, the cable will be subject to overload. Furthermore, the protective device would take a long time to trip under this overload condition. Over time this persistent overload could potentially damage the cable, isolator, circuit-breaker and shower, leading to a potential fire hazard.

To satisfy the requirements of BS 7671, circuit upgrades will be required to accommodate the new shower. Alternatively the client may decide to replace the shower with one of the same rating or lower.

Calculating the maximum shower rating for an existing circuit

Using the power rating of the existing faulty 7.5 kW shower, the requirements of BS 7671 are met.

A simple method to determine the maximum power rating of the replacement electric shower, without the need to upgrade the circuit, is to multiply the circuit-breaker rating by the phase voltage as shown in Equation 6.

It may not always be the case that the existing circuit satisfies BS 7671. It is possible the existing circuit may be found to be non-compliant. A common example of this is where an additional layer of thermal insulation has been installed within the loft, further covering the cable. This can change the installation method from 100 to 101, which reduces the current carrying capacity of the cable by approximately 20%.

Further verification

The article, up to this point, has focused on ensuring that the current-carrying capacity of the circuit is suitable for the new load. Further checks are required to ensure that the circuit is in a satisfactory condition for continued use.Further checks include inspections of the existing circuit to ensure it has been operating correctly with the existing shower. These inspections would include checking the circuit-breaker, circuit accessories and cable terminations for signs of thermal damage.

Testing will supplement these inspections to ensure the requirements of automatic disconnection of supply and additional protection are met. Voltage drop verification for long circuits should also be considered.

Summary

When replacing an electric shower, the person responsible for undertaking the proposed work should ensure that the existing circuit meets the necessary requirements of BS 7671 before making an addition or alteration, and in particular, that the circuit has sufficient capacity for the proposed replacement shower. The current demand of an electric shower is proportional to the voltage of the installation and this is something that should not be overlooked, as it may be the difference between a compliant and non-compliant design. Additionally, the inspector may find during checks that the circuit is not suitable for the existing load. This can be due to energy efficiency measures that have been carried out after the original installation, such as the installation of additional loft insulation.