This article discusses differences between initial and periodic verification pertinent to testing and suggests a sequence of testing which may be appropriate for carrying out a periodic inspection.

BS 7671 contains clear requirements in respect of the order in which many tests have to be carried out during initial verification. However, no such information is given in respect of testing carried out as part of a periodic inspection of a property. This article discusses some differences between initial and periodic verification pertinent to testing and suggests a sequence of testing which may be appropriate for use when carrying out a periodic inspection.

Regulation 643.1 states that the tests described in regulations 643.2 to 643.11, where relevant and appropriate for the installation being tested, shall be carried out. It also states that the tests described in Regulations:

It is important that these tests are performed in the correct sequence. For example, we must verify the continuity of a conductor before carrying out an insulation resistance test to confirm that the test voltage is applied to the full length of all of the relevant conductor(s) to be tested. Without verifying end-to-end continuity first the insulation resistance test might only be applied to a part of the conductor(s).

Regulation 643.1 advises that: ‘If any test indicates a failure to comply, that test and any preceding test, the results of which may have been influenced by the fault indicated, shall be repeated after the fault has been rectified’.

Additionally, where the installation incorporates an earth electrode, the testing described in regulation 643.7.2 shall also be carried out prior to the installation, or that part being worked on, being energised.

Thereafter, the applicable tests described in regulations:

Any sequence of testing employed during a periodic inspection must take account of the differences between initial and periodic verification. Perhaps the key difference is that, in many cases, an existing installation will be connected to a supply and will be energised prior to the periodic inspection taking place.

Where this is the case, it would seem wise to carry out some testing at the origin, with the installation energised, to determine the adequacy, or otherwise, of the supply arrangement before progressing to any further inspection or testing within the installation.

This preliminary testing might identify damage, defects or non-compliances which render the installation immediately or potentially dangerous and which may prevent, or severely limit, any further testing activities. For example, incorrect polarity of the incoming supply, or inadequacies in the earthing arrangement for the installation.

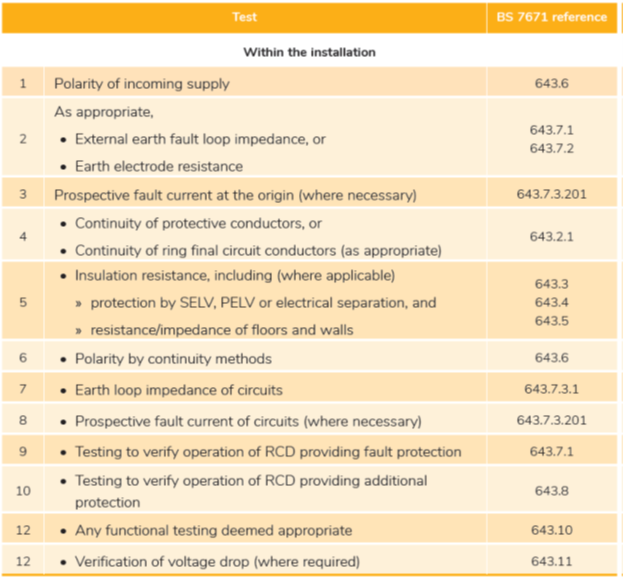

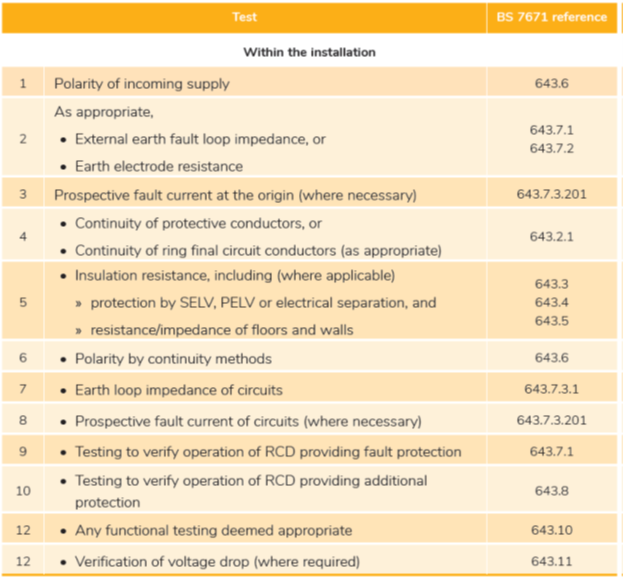

The following sequence reproduced from the NICIEC publication Site Guide (18th Edition AMD2), may be appropriate, bearing in mind that not all the tests listed will be applicable to any particular installation:

Initial verification

Section 643 of BS 7671 contains requirements for the testing of an electrical installation during initial verification.Regulation 643.1 states that the tests described in regulations 643.2 to 643.11, where relevant and appropriate for the installation being tested, shall be carried out. It also states that the tests described in Regulations:

- 643.2 Continuity of conductors

- 643.3 Insulation resistance

- 643.4 Protection by SELV, PELV or by electrical separation

- 643.5 Insulation resistance/impedance of floors and walls

- 643.6 Polarity

It is important that these tests are performed in the correct sequence. For example, we must verify the continuity of a conductor before carrying out an insulation resistance test to confirm that the test voltage is applied to the full length of all of the relevant conductor(s) to be tested. Without verifying end-to-end continuity first the insulation resistance test might only be applied to a part of the conductor(s).

Regulation 643.1 advises that: ‘If any test indicates a failure to comply, that test and any preceding test, the results of which may have been influenced by the fault indicated, shall be repeated after the fault has been rectified’.

Additionally, where the installation incorporates an earth electrode, the testing described in regulation 643.7.2 shall also be carried out prior to the installation, or that part being worked on, being energised.

Thereafter, the applicable tests described in regulations:

- 643.7.3 Earth fault loop impedance and prospective fault current

- 643.8 Additional protection

- 643.9 Check of phase sequence

- 643.10 Functional testing

Periodic verification

BS 7671 does not state a sequence for testing forming part of periodic inspection activities. It also does not state which tests should be carried out during periodic inspection and testing. However regulation 651.2 states that the periodic inspection shall be supplemented by appropriate testing and measurements from Chapter 64.Any sequence of testing employed during a periodic inspection must take account of the differences between initial and periodic verification. Perhaps the key difference is that, in many cases, an existing installation will be connected to a supply and will be energised prior to the periodic inspection taking place.

Where this is the case, it would seem wise to carry out some testing at the origin, with the installation energised, to determine the adequacy, or otherwise, of the supply arrangement before progressing to any further inspection or testing within the installation.

This preliminary testing might identify damage, defects or non-compliances which render the installation immediately or potentially dangerous and which may prevent, or severely limit, any further testing activities. For example, incorrect polarity of the incoming supply, or inadequacies in the earthing arrangement for the installation.

The following sequence reproduced from the NICIEC publication Site Guide (18th Edition AMD2), may be appropriate, bearing in mind that not all the tests listed will be applicable to any particular installation: