This article explores the importance of proper electrical connections and maintaining best working practices.

Poor connections, particularly those involving neutral conductors, are often identified during electrical inspection and testing, with some incidents periodically reported to the NICEIC. If these issues remain unrectified, they can lead to thermal distress, conductor/connection failure or possibly cause fires. It is essential therefore to apply the same level of diligence when connecting or inspecting neutral conductors as with any other live conductor.

.png)

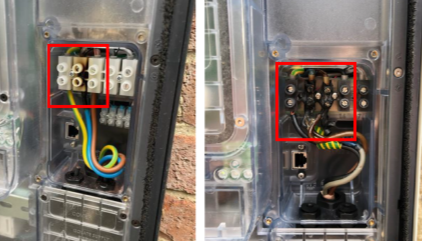

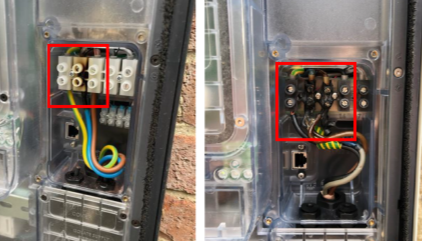

Fig 1 Thermal damage at terminations of EV charging equipment most likely caused by loose connections (Image courtesy Cenex, 2021)

‘Live part. A conductor or conductive part intended to be energized in normal use, including a neutral conductor but, by convention, not a PEN conductor’.

Typically, in the least complex domestic and similar premises, the current in the neutral conductor is equal to that in the line conductor.

Regulation 524.2.1 requires that in single-phase, two-wire circuits, the neutral conductor should have a cross-sectional area (csa) not less than that of the line conductor in all cases.

Regulation 524.2.1 also requires that the neutral conductor, if any, shall have a cross-sectional area (csa) not less than that of the line conductor:

It should be remembered that the current in the neutral conductor may be greater than that in any of the phase conductors due to the imbalance between the connected single-phase loads, caused by a combination of varying current demands and/or power factors in each phase.

Additionally, consideration must also be given to overcurrent in the neutral conductor of a circuit (single-phase or three-phase) during an overload or short-circuit.

However, it is permissible within a three-phase installation to have a neutral conductor with a reduced csa where each line conductor has a csa greater than 16 mm2 for copper or 25 mm2 for aluminium, and where the conditions of regulation 524.2.3 are met.

Inadequate connections made in current-carrying conductors, including a neutral conductor, can lead to an increase in resistance and a subsequent rise in temperature at the point of connection. Such conditions can pose a risk of thermal distress, damage to electrical equipment and/or its surroundings, or lead to a potential risk of fire. Poor connections can also increase circuit impedance, which may result in the failure of, or a delay in operation of, an overcurrent protective device under fault conditions.

Arcing within an accessory or equipment resulting from a loose connection can also increase the risk of thermal damage. When a gap is formed between the points of contact within a poor connection an electric arc can develop. In such cases, a high-temperature discharge occurs in the form of hot plasma, created when electrical current flows through the ionized air, between the contact points within the poor termination. Such high temperatures (in excess of 1,000 °C) can lead to subsequent breakdown in both the conductive and insulating materials of the conductor or contact terminal allowing the formation of carbon deposits, which further exacerbates the thermal process.

To better understand the potential heat generation that can be produced at a poor connection, consider the following example:

If the resistance of a defective connection between a neutral conductor and the terminal of the main switch of a consumer unit is found to be 2 Ω and the current flowing in the neutral conductor is measured at 30 A, under these conditions, the heating power (P) generated at the connection would be:

There is a fundamental requirement within Section 134 of BS 7671 that every electrical installation is subjected to appropriate inspection and testing:

This is also supported by regulation 641.1 which also calls for inspection and testing to be carried out both during the construction of the installation and on completion of the work.

Such routine inspection and testing aims to help identify any signs of wear, corrosion or loosening of connections before a dangerous situation arises, thereby mitigating the risk of thermal damage and/or fire.

.png)

Fig 1 Thermal damage at terminations of EV charging equipment most likely caused by loose connections (Image courtesy Cenex, 2021)

Introduction

It should be remembered that a neutral conductor is a live conductor. Part 2 of BS 7671 defines a live part as:‘Live part. A conductor or conductive part intended to be energized in normal use, including a neutral conductor but, by convention, not a PEN conductor’.

Typically, in the least complex domestic and similar premises, the current in the neutral conductor is equal to that in the line conductor.

Regulation 524.2.1 requires that in single-phase, two-wire circuits, the neutral conductor should have a cross-sectional area (csa) not less than that of the line conductor in all cases.

Regulation 524.2.1 also requires that the neutral conductor, if any, shall have a cross-sectional area (csa) not less than that of the line conductor:

- in three-phase and single-phase three-wire circuits, where the size of the line conductors is less than or equal to 16 mm2 for copper, or 25 mm2 for aluminium, and

- where the neutral conductor carries current without a corresponding reduction in load current of the line conductors, typically in the presence of harmonics, and where the neutral conductor must take account of the current-carrying capacity of the circuit (523.6.3).

It should be remembered that the current in the neutral conductor may be greater than that in any of the phase conductors due to the imbalance between the connected single-phase loads, caused by a combination of varying current demands and/or power factors in each phase.

Additionally, consideration must also be given to overcurrent in the neutral conductor of a circuit (single-phase or three-phase) during an overload or short-circuit.

However, it is permissible within a three-phase installation to have a neutral conductor with a reduced csa where each line conductor has a csa greater than 16 mm2 for copper or 25 mm2 for aluminium, and where the conditions of regulation 524.2.3 are met.

Electrical connections

Every connection between conductors or between a conductor and other equipment shall provide durable electrical continuity, and adequate mechanical strength and protection (526.1).Inadequate connections made in current-carrying conductors, including a neutral conductor, can lead to an increase in resistance and a subsequent rise in temperature at the point of connection. Such conditions can pose a risk of thermal distress, damage to electrical equipment and/or its surroundings, or lead to a potential risk of fire. Poor connections can also increase circuit impedance, which may result in the failure of, or a delay in operation of, an overcurrent protective device under fault conditions.

Arcing within an accessory or equipment resulting from a loose connection can also increase the risk of thermal damage. When a gap is formed between the points of contact within a poor connection an electric arc can develop. In such cases, a high-temperature discharge occurs in the form of hot plasma, created when electrical current flows through the ionized air, between the contact points within the poor termination. Such high temperatures (in excess of 1,000 °C) can lead to subsequent breakdown in both the conductive and insulating materials of the conductor or contact terminal allowing the formation of carbon deposits, which further exacerbates the thermal process.

To better understand the potential heat generation that can be produced at a poor connection, consider the following example:

If the resistance of a defective connection between a neutral conductor and the terminal of the main switch of a consumer unit is found to be 2 Ω and the current flowing in the neutral conductor is measured at 30 A, under these conditions, the heating power (P) generated at the connection would be:

30 ² × 2 = 1,800 W

Preventative measures and best practice

It is important to maintain good working practices during installation work to ensure proper termination of electrical connections and equipment. The materials used for terminating such a connection must also be suitable for the intended application. Regulation group 526 outlines the considerations for selecting the appropriate means of connection.There is a fundamental requirement within Section 134 of BS 7671 that every electrical installation is subjected to appropriate inspection and testing:

- during construction, and

- on completion,

This is also supported by regulation 641.1 which also calls for inspection and testing to be carried out both during the construction of the installation and on completion of the work.

Such routine inspection and testing aims to help identify any signs of wear, corrosion or loosening of connections before a dangerous situation arises, thereby mitigating the risk of thermal damage and/or fire.